American National Standard

Test Procedure and Acceptance Criteria for Factory Applied Finish Coatings for Steel Doors and Frames

ANSI/SDI A250.3-2019

View PDF

Table of Contents

Tables

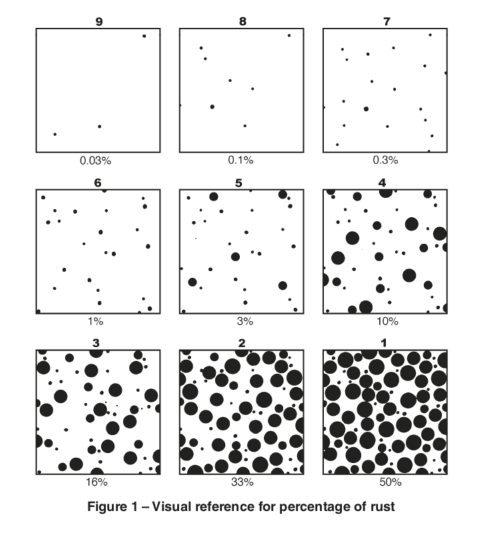

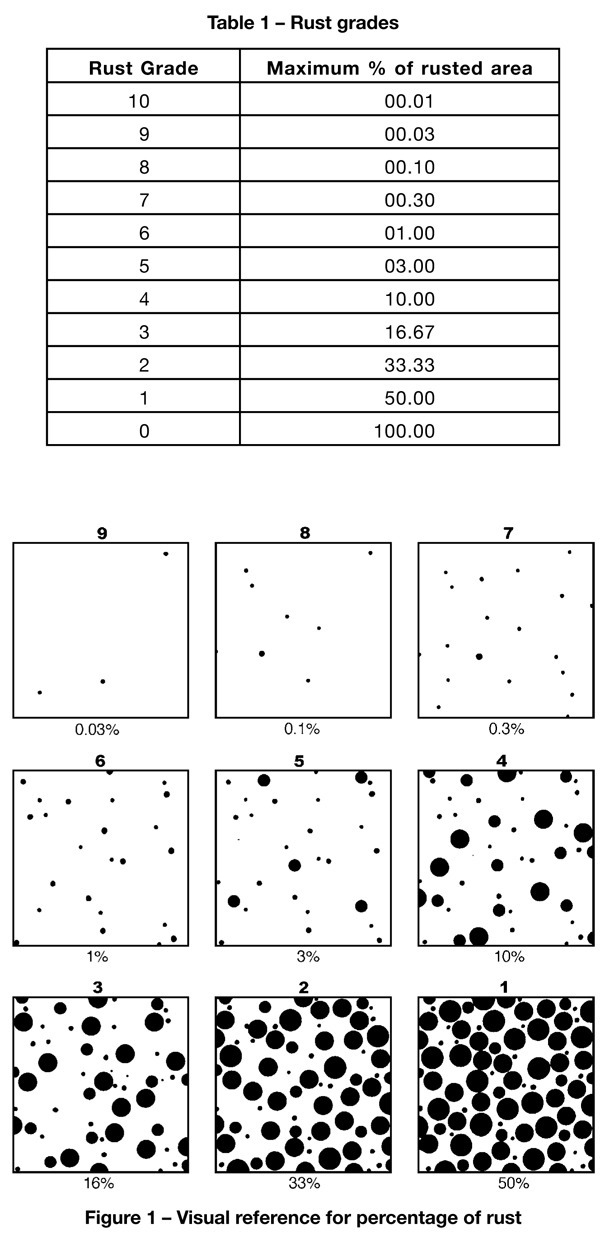

- Rust grades

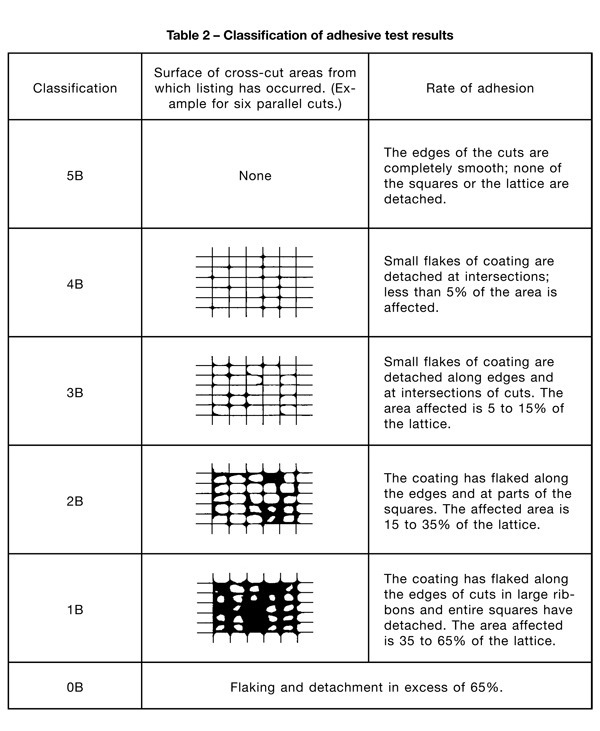

- Classification of adhesive test results

Figures

- Visual reference for percentage of rust

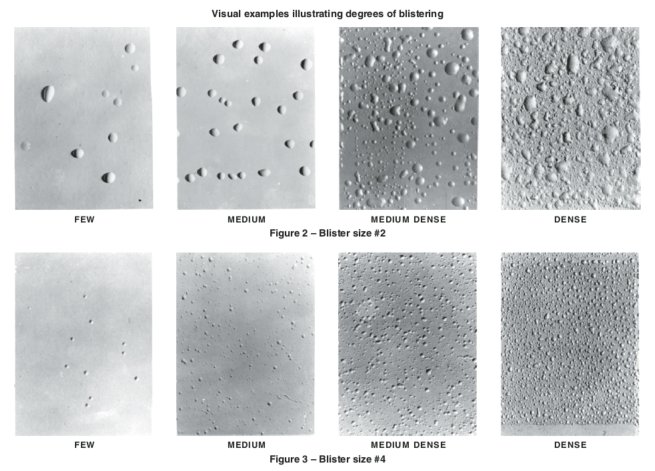

- Blister size #2

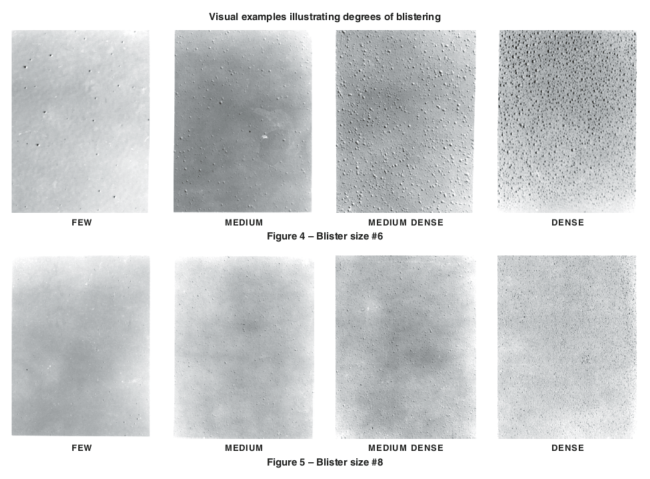

- Blister size #4

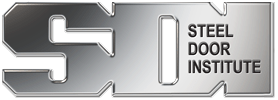

- Blister size #6

- Blister size #8

1. General

1.1 Scope

These methods prescribe the procedures to be followed in the selection of material, chemical preparation, coating application, testing, and evaluation of factory applied finish coatings for steel doors and frames. Coatings covered by this standard include paints, stains, clear coats, and powder coats.

1.2 Reference Documents

- ASTM B117-18 — Standard Practice for Operating Salt Spray (Fog) Testing Apparatus

- ASTM D1654-08 (2016)e1 — Standard Test Method for Evaluation of Painted or Coated Specimens Subjected to Corrosive Environments

- ASTM D4585 / D4585M-18 — Standard Practice for Testing Water Resistance of Coatings Using Controlled Condensation

- ASTM G154-16 — Standard Practice for Operating Fluorescent Light Apparatus for UV Exposure of Nonmetallic Materials

- ASTM D4587-11 — Standard Practice for Fluorescent UV-Condensation Exposures of Paint and Related Coatings

- ASTM D2794-93 (2019) — Standard Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact)

- ASTM D3359-17 — Standard Test Method for Measuring Adhesion by the Tape Test

- ASTM D4060-01 — Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser

- ASTM D610-08 (2019) — Standard Test Method for Evaluating Degree of Rusting on Painted Steel Surfaces

- ASTM D714-02 (2017) — Standard Test Method for Evaluating Degree of Blistering of Paints

- ASTM D4214-07 (2015) — Standard Test Method for Evaluating Degree of Chalking of Exterior Paint Films

- ASTM D523-14 (2018) — Standard Test Method for Specular Gloss

- ASTM D2244-16 — Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates

2. Material

2.1 — The test specimen shall be the exact type and gauge of steel as used in the manufacture of the product. The specimen shall be a minimum of 4″ (102 mm) × 6″ (152 mm) with a 1/4″ (6.4 mm) hole at the center of the 4″ (102 mm) width, 1/2″ (12.7 mm) in from the end. Identification marks shall be added to the specimen as required for control purposes. The test specimen shall be handled at all stages of the process with clean gloves to prevent contamination.

2.2 — The specimen(s) shall be hung using a method representat ive of that used in production.

2.3 — The test specimen(s) shall be cleaned, pretreated and coated in accordance with the manufacturers normal production method and procedure. All coating weights used on test specimens shall be documented and representative of the individual manufacturer’s normal production material.

2.4 — At the end of the coating cycle, the specimen(s) shall be removed from the coating system and handled carefully. The coated surface of the specimen shall not be handled or come in contact with other objects in such a way as to disrupt the coated surface.

2.5 — Specimens shall be allowed to age at an ambient room temperature, for a minimum 72 hour duration, before any testing commences.

3. Testing

3.1 Salt spray test

Apparatus – The apparatus used for salt spray testing shall be of such design as to conform to ASTM B117-03, “Standard Practice for Operating Salt Spray (Fog) Testing Apparatus.”

Test performance – Salt spray testing shall be conducted as specified in ASTM B117-03, “Standard Practice for Operating Salt Spray (Fog) Testing Apparatus,” for a test period of 120 continuous hours. The test specimen shall be scribed with an “X” per ASTM D1654-92, “Standard Test Method for Evaluation of Painted or Coated Specimens Subjected to Corrosive Environments”, sections 4.1 and 5.1.

3.2 Condensation testing (humidity)

Apparatus – The apparatus used for condensation (humidity) testing shall be of such design as to conform to ASTM D4585-99, “Standard Practice for Testing Water Resistance of Coatings Using Controlled Condensation.”

Test performance – Condensation (humidity) testing shall be conducted as specified in ASTM D4585-99, “Standard Practice for Testing Water Resistance of Coatings Using Controlled Condensation,” for a test period of 480 continuous hours. Exposure temperatures shall be maintained at a minimum of 100°F (38°C). Actual test temperature shall be noted in the report.

3.3 Accelerated weathering test

Apparatus – The apparatus used for accelerated weathering testing shall be of such design as to conform to ASTM G154-04, “Standard Practice for Operating Fluorescent Light Apparatus for UV Exposure of Nonmetallic Materials.” The bulb type used shall be a UVA340.

Test performance – Accelerated weathering testing shall be conducted as specified in ASTM D4587-01, “Standard Practice for Fluorescent UV-Condensation Exposures of Paint and Related Coatings” for a test period of 300 hours duration. The cycle schedule for operating this type of equipment shall be 18 hours of light exposure at 140°F (60°C) followed by a 6 hour condensat ion cycle at 120°F (49°C).

3.4 Impact test

The coating shall be tested per ASTM D2794- 93(2004), “Standard Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact),” with 20 inch pounds of direct impact using a Gardner Impact Tester with a 1/2″ (12.7 mm) diameter ball or punch at room temperature of 70°-75°F (21°C-24°C). The test specimen shall be impacted at three locations on the panel that have a dry film thickness within the tolerance range for the coating process. Apply one-inch (25.4 mm) wide, #600 Scotch cellophane pressure-sensitive tape firmly to the impact area and pull off sharply.

3.5 Film adhesion test

The coating film adhesion shall be tested in accordance with method “B” of ASTM D3359-02, “Standard Test Method for Measuring Adhesion by the Tape Test.” A total of (11) parallel cuts are made with a sharp instrument, 0.039″ (1 mm) apart in both a vertical and horizontal direction forming a grid. One-inch (25.4 mm) wide #600 Scotch cellophane pressure-sensitive tape is then firmly applied to the scribed surface and rapidly removed.

3.6 Abrasion test

The coating film shall be tested with a Taber Abraser Testing Apparatus using a No. CS-10 Resilient Calibrase Wheel in accordance with ASTM D4060. The specimen shall be run for a maximum of 1000 cycles, or until breakthrough of the finish coating occurs.

4. Acceptance criteria

4.1 Salt spray resistance

The coating film on the unscored surface of the test specimen shall have a rust grade of no less than 6 as defined in ASTM D6101. See Table 1 and Figure 1 herein for evaluation of the rust grades. The coating film at the scribe line shall not be undercut by rust more than 1/8″ (3.2 mm) or a Rating Number 6 on each side of the scribe line when evaluated in accordance with ASTM D1654. See Table 2 herein, “Rating of failure at scribe (Procedure A)”.

4.2 Condensation resistance

The coating film shall be allowed to exhibit the dense pattern of #8 blisters, but shall have no more than the “few” pattern of #6 blisters as illustrated in the photographic reference ASTM D714-02, “Standard Test Method for Evaluating Degree of Blistering of Paints. ” Testing shall be in accordance with Paragraph 3.2. Visual representations of the various degrees of blistering are shown in Figures 2 through 5 of this document.

4.3 Accelerated weathering resistance

When tested in accordance with Paragraph 3.3 herein, the paint film shall exhibit the following traits:

4.3.1 — No rust, checking, cracking, erosion or flaking shall be present.

4.3.2 — No more than a few #6 blisters as illustrated in Figure 4 and in ASTM D714-02, “Standard Test Method for Evaluating Degree of Blistering of Paint.”

4.3.3 — A degree of chalking not to exceed #8 as illustrated in Figure 6 and in test method B of ASTM D4214-98, “Standard Test Method for Evaluating Degree of Chalking of Exterior Paint Films.”

4.3.4 — No more than a 50% decrease in gloss when tested in accordance with ASTM D523- 89(1999), “Standard Test Method for Specular Gloss.”

4.3.5 — No more than a 10% change in color (fade) when tested in accordance with ASTM D2244-02e1, “Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates.”

4.4 Impact test

No coating film removal shall occur other than at an area 1/8″ (3.2 mm) in diameter at the center of the impact area, when tested in accordance with Paragraph 3.4.

4.5 Film adhesion

There shall be no adhesion loss less than a grade 3B as defined in ASTM D3359-02. This grade represents a film removal of between 5 and 15%. Table 2 on page 8 illustrates the various classifications for adhesion loss.

4.6 Abrasion resistance

The coating film shall have a wear index of 100 (.10 mg weight loss per cycle) or less when tested in accordance with Paragraph 3.6 herein.

5. Report

5.1 — The report shall cover the date the test was per formed and the issue date of the report .

5.2 — Identification of the specimen tested, source of supply, manufacturer, model or series number, or both, and any other pertinent information.

5.3 — A detailed description of the specimen or specimens tested shall include the type of prime or barrier coating if used, the method of coating application, the procedure used to cure it and the dry film thickness.

5.4 — Any modifications made on the test specimen to obtain the values of acceptance shall be noted and described.

5.5 — A statement that the test or tests were conducted in accordance with the methods and procedures as specified herein. If deviations from these methods and procedures were made, they shall be described in the report.

5.6 — When the test is made to check the conformance of the unit specimen to test requirements of a particular specification, the identification or description of the specification shall be included in the report.

6. General

6.1 Testing laboratory

All tests shall be conducted and certified by a nationally recognized, independent testing laboratory.

6.2 Certification

When reference is made to this specification the following statement shall be used: “Finish coating has been tested in conformance with ANSI Standard A250.3-2006.”

Tables

Figures