Electronic Hinge Preparations

SDI 130-19

View PDF

1. Purpose

It is the intention of this document to furnish users of standard steel frames with practical information regarding an acceptable method for preparing frames for 4-1/2″, 5″ or continuous electric hinges. This document will allow frame manufacturers to provide frames prior to having knowledge of the specific electric hinge being used.

2. Scope

The information contained herein pertains to frames manufactured in accordance with ANSI A250.8. The preparation as defined herein will accommodate the majority of electric hinges sold. It is the responsibility of the hardware specifier to assure compatible hinges are used.

3. Reference Documents

- ANSI/SDI A250.6 Recommended Practice for Hardware Reinforcings on Standard Steel Doors and Frames

- ANSI/SDI A250.8 SDI 100 Specifications for Standard Steel Doors & Frames

- ANSI/BHMA A156.7 Template Hinge Dimensions

- ANSI/BHMA A156.115 Hardware Preparation in Steel Doors and Steel Frames

4. Tolerances

All values which do not carry specific tolerances or are not marked maximum or minimum shall have the following tolerances: Linear dimensions shall be ± 1/16 in. (1.6 mm). Weight or force shall be ± 2%. Angles shall be ± 2 degrees. Where only minus tolerances are given, the dimensions are permitted to be exceeded at the option of the manufacturers.

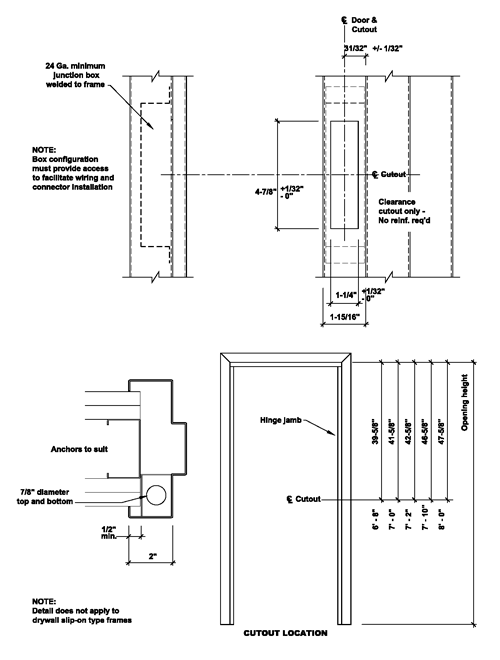

5. Location

The preparation for electric hinges is intended to be non-load bearing. Therefore it shall be located in the center hinge preparation on frames with 1-1/2 pair of hinges, and on the second hinge from the bottom on frames with 2 pair of hinges.

6. Hinge Reinforcement

The hinge reinforcement shall comply with ANSI A250.6 and ANSI A250.8, and shall incorporate cutouts as shown in Figures 1, 2, 3 and 4.

7. Junction Box

A junction box may be provided to facilitate wiring and connector installation. In addition, a hole shall be provided at the top and bottom of the junction box to facilitate conduit (see Figure 4). It is the responsibility of the electrical contractor to plug any unused holes.

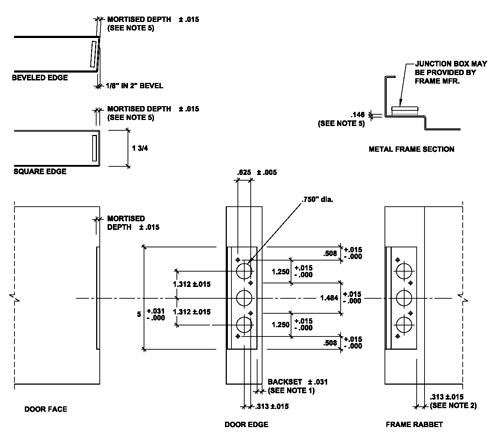

Figure 1 – Preparation of 1 3/4″ Steel Doors & Frames for 5″ Full Mortise Electric Hinge

.

Note 1: The hinge backset on the door varies by hollow metal door manufactures from 3/16″ to 1/4″.

Note 2: The hinge backset on the frame varies by hollow metal frame manufactures from 5/16″ to 3/8″.

Note 3: Extra holes may occur in the reinforcement for tooling and installation fixturing.

Note 4: Some manufacturers offer a removable feature (e.g. – wire, shim, standoff projection) to allow conversion of a standard weight preparation for use with heavy weight hinge butt.

Note 5: The most common mortise depths are in accordance with ANSI/BHMA A156.1 as follows:

- Standard Weight butt 0.146″

- Heavy weight butt 0.190″.

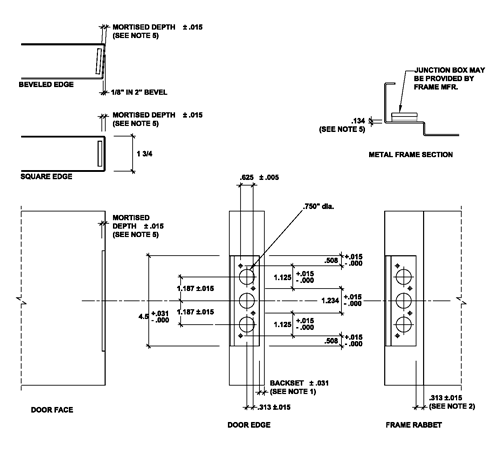

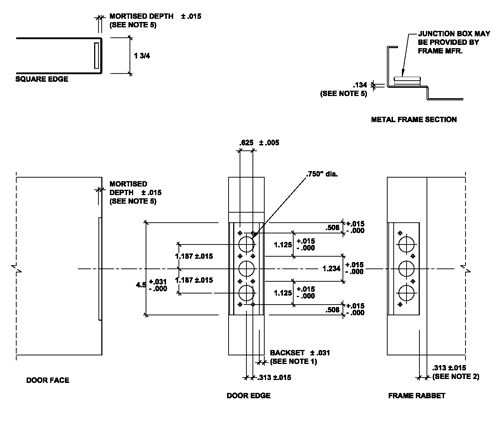

Figure 2 – Preparation of 1 3/4″ Steel Doors & Frames for 4 1/2″ Full Mortise Electric Hinge

.

Note 1: The hinge backset on the door varies by hollow metal door manufactures from 3/16″ to 1/4″ when hinge filler is in place.

Note 2: The hinge backset on the frame varies by hollow metal frame manufactures from 5/16″ to 3/8″

Note 3: Extra holes may occur in the reinforcement for tooling and installation fixturing.

Note 4: Some manufacturers offer a removable feature (e.g. – wire, shim, standoff projection) to allow conversion of a standard weight preparation for use with heavy weight hinge butt.

Note 5: The most common mortise depths are in accordance with ANSI/BHMA A156.1 as follows:

- Standard Weight butt 0.134″

- Heavy weight butt 0.180″.

Figure 3 – Preparation of 1 3/4″ Steel Doors & Frames for 4 1/2″ Full Mortise Electric Hinge Non-handed

.

Note 1: The hinge backset on the door varies by hollow metal door manufactures from 3/16″ to 1/4″ when hinge filler is in place.

Note 2: The hinge backset on the frame varies by hollow metal frame manufactures from 5/16″ to 3/8″

Note 3: Extra holes may occur in the reinforcement for tooling and installation fixturing.

Note 4: Some manufacturers offer a removable feature (e.g. – wire, shim, standoff projection) to allow conversion of a standard weight preparation for use with heavy weight hinge butt.

Note 5: The most common mortise depths are in accordance with ANSI/BHMA A156.1 as follows:

- Standard Weight butt 0.134″

- Heavy weight butt 0.180″.

Figure 4 – Electrified Continuous Hinge Preparation on Standard Steel Frame